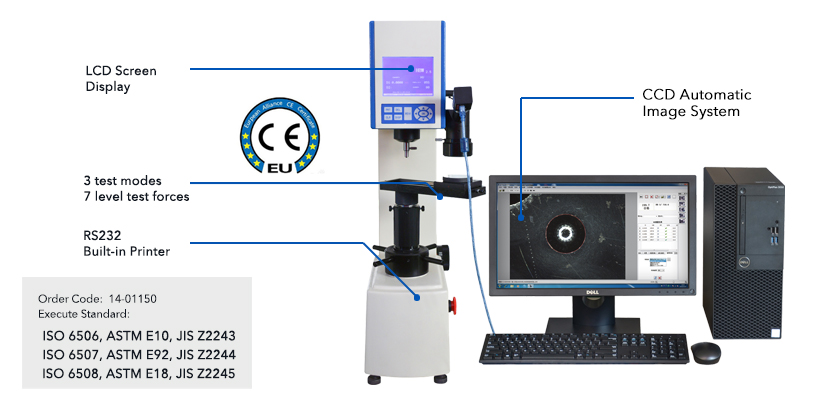

BRV-187.5D+CCD Brinell Rockwell & Vickers Hardness Teste

Instruction

InstructionBRV-187.5D+CCD is a multi-functional digital hardness tester with Brinell, Rockwell &Vickers. Widely used and easy to operate, popular choice for industrial enterprises and scientific research institutes.

Suitable for hardened and surface hardened steel, hard alloy steel, casting parts, non-ferrous metals, various kinds of hardening and tempering steel and tempered steel, carburized steel sheet, soft metals, surface heat treating and chemical treating materials etc.

Versatility & Reliability

3 test modes and 7 level of test forces, easy to test Brinell, Rockwell, Vickers hardness

3 test modes and 7 level of test forces, easy to test Brinell, Rockwell, Vickers hardness Conversion scales of different kinds of hardness

Conversion scales of different kinds of hardnessEasy Operation and Output

Test force loading, dwelling, unloading adopts automatic shifting for easy and fast operation

Test force loading, dwelling, unloading adopts automatic shifting for easy and fast operation LCD screen display and set the current scale, force, indenter, indenter type, dwell time and hardness conversion etc.

LCD screen display and set the current scale, force, indenter, indenter type, dwell time and hardness conversion etc. Automatic calculation of maximum, minimum and average value

Automatic calculation of maximum, minimum and average value Test results be saved and printed out by Built-in printer. Also equipped with RS232 interface

Test results be saved and printed out by Built-in printer. Also equipped with RS232 interfaceCCD Automatic Image System

Basic Functions

Basic FunctionsSystem can realize image capture, calibration, image processing, geometric measurement, document annotation, album management, and fixed-size printing, etc.

Automatic Measurement & Hardness Conversion

Automatic Measurement & Hardness ConversionAutomatic measurement of indentation diameter, display Brinell, Vickers hardness value, the system can convert the measured hardness value into other hardness values such as HR hardness

Data Statistics & Alarm

Data Statistics & AlarmAutomatically calculates average value, variance and other values; automatically marks abnormal values, automatically alarms when the hardness exceeds the specified value

Automatic Calibration

Automatic CalibrationCalibration function is convenient for measuring indentation size and can be calibrated. If equipped with a calibration grid, system can automatically perform full-scale calibration on intersection points of the calibration grid to reduce measurement errors caused by lens distortion

Test Report

Test Report Automatically generate a report in WORD or EXCEL format, and the report template can be provided by the user

Technical Specification

Technical Specification| Item | Spec. |

| Rockwell Test Force | 60kgf (588.4N), 100kgf (980.7N), 150kgf (1471N) |

| Brinell Test Force | 30kgf (294.2N), 31.25kgf (306.5N), 62.5kgf (612.9N), 100kgf (980.7N), 187.5kgf (1839N) |

| Vickers Test Force | 30kgf (294.2N), 100kgf (980.7N) |

| Indenter |

Diamond Rockwell Indenter, Diamond Vickers Indenter, Φ1.588mm, Φ2.5mm, Φ5mmBall Indenter |

| Hardness Reading | LCD Screen Display |

| Test Scale | HRA, HRBW, HRC, HRD, HBW1/30, HBW2.5/31.25, HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5, HBW10/100, HV30, HV100 |

| Conversion Scale | HV, HK, HRA, HRBW, HRC, HRD, HREW, HRFW, HRGW, HRKW, HR15N, HR30N, HR45N, HR15TW, HR30TW, HR45TW, HS, HBW |

| Magnification | Brinell: 37.5×, Vickers: 75× |

| Min. Measuring Unit | Brinell: 0.5μm, Vickers: 0.25μm |

| Hardness Resolution | Rockwell: 0.1HR, Brinell: 0.1HBW, Vickers: 0.1HV |

| Dwell Time | 0-60 s |

| Data Output | Built-in Printer, RS232 Interface |

| Max. Sample Height | Rockwell: 185mm, Brinell: 100mm, Vickers: 115mm |

| Throat Depth | 165mm |

| Power Supply | AC220V, 50Hz |

| Execute Standard |

ISO 6508, ASTM E18, JIS Z2245, GB/T 230.2 ISO 6506, ASTM E10, JIS Z2243, GB/T 231.2 ISO 6507, ASTM E92, JIS Z2244, GB/T 4340.2 |

| Dimension |

Machine: 520 W ×240 D ×740 H mm Packing: 650 W ×370 D ×980 H mm |

| Weight |

Net Weight: 80 kg Gross Weight: 105 kg |

- Previous:Sorry, no more.

- Next:Sorry, no more.

Send your message to us: